Safety and health initiatives

Based on the principle of “Respect for Human Rights and Friendly Work Environment” set forth in the SCREEN Group CSR Charter and Code of Conduct, we have established the Occupational Safety and Health Policy. In line with the policy, we endeavor to provide employees with safe and healthy workplace environments, and we comply with all relevant occupational safety-related laws, regulations, and rules. As our products grow more advanced, multifactor operational safety risks are increasing. In light of such changes, we plan and implement measures to ensure safe and healthy workplaces and take concrete steps to prevent occupational accidents.

Occupational Safety and Health Policy

Wellness Initiatives

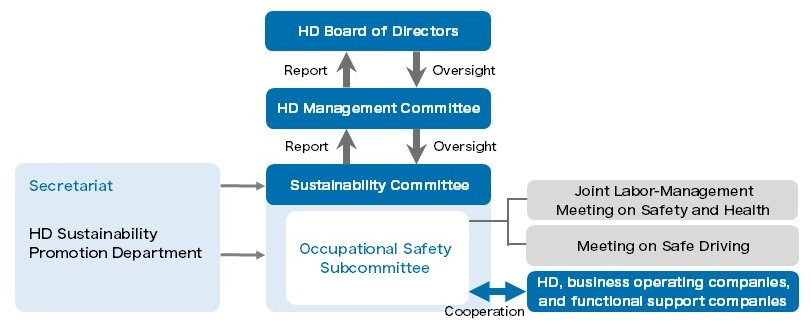

Promotional framework

The Sustainability Committee meets three times a year. The committee’s decision maker is the SCREEN Holdings president and CEO, its chair is the SCREEN Holdings senior sustainability strategy officer, and it comprises the presidents and CSR officers of the business operating and functional support companies. The committee approves targets and action plans, monitors their progress and results, and issues improvement instructions as part of efforts toward continuous improvement.

Under the Sustainability Committee, the Occupational Safety Subcommittee leads group-wide efforts to determine safety and health-related plans and measures. The departments that promote sustainability serve as operational secretariat for the Sustainability Committee, and Occupational Safety Subcommittee, reinforcing coordination across SCREEN Holdings, the business operating companies, and the functional support companies.

Metrics and targets

To prevent occupational accidents, we implement risk assessments and advance safety verifications for a wide range of work processes, such as product development, manufacturing, and equipment installation. In FY2025/03, the number of occupational accidents at group and partner companies in Japan was down 17.5% from the previous fiscal year.

There were no deaths or serious accidents during the fiscal year.

To achieve even safer work environments, through risk assessments and occupational safety educational activities, we will strengthen initiatives aimed at preventing occupational accidents, including eliminating hazards. Going forward, we will continue and reinforce initiatives to prevent occupational accidents, aiming to achieve our targets.

Note: More detailed data on safety and health can be found in Sustainability Data or the Sustainability Data Book 2025.

● Occupational accidents

FY2027/03 target: 33% reduction compared with FY2024/03 (26 or fewer1)

FY2025/03 result: 17.5% reduction compared with FY2024/03 (33 total)

1. Revised the scope to occupational accidents where company negligence is recognized as a cause

/Number_of_occupational_accidents_resulting_E.png)

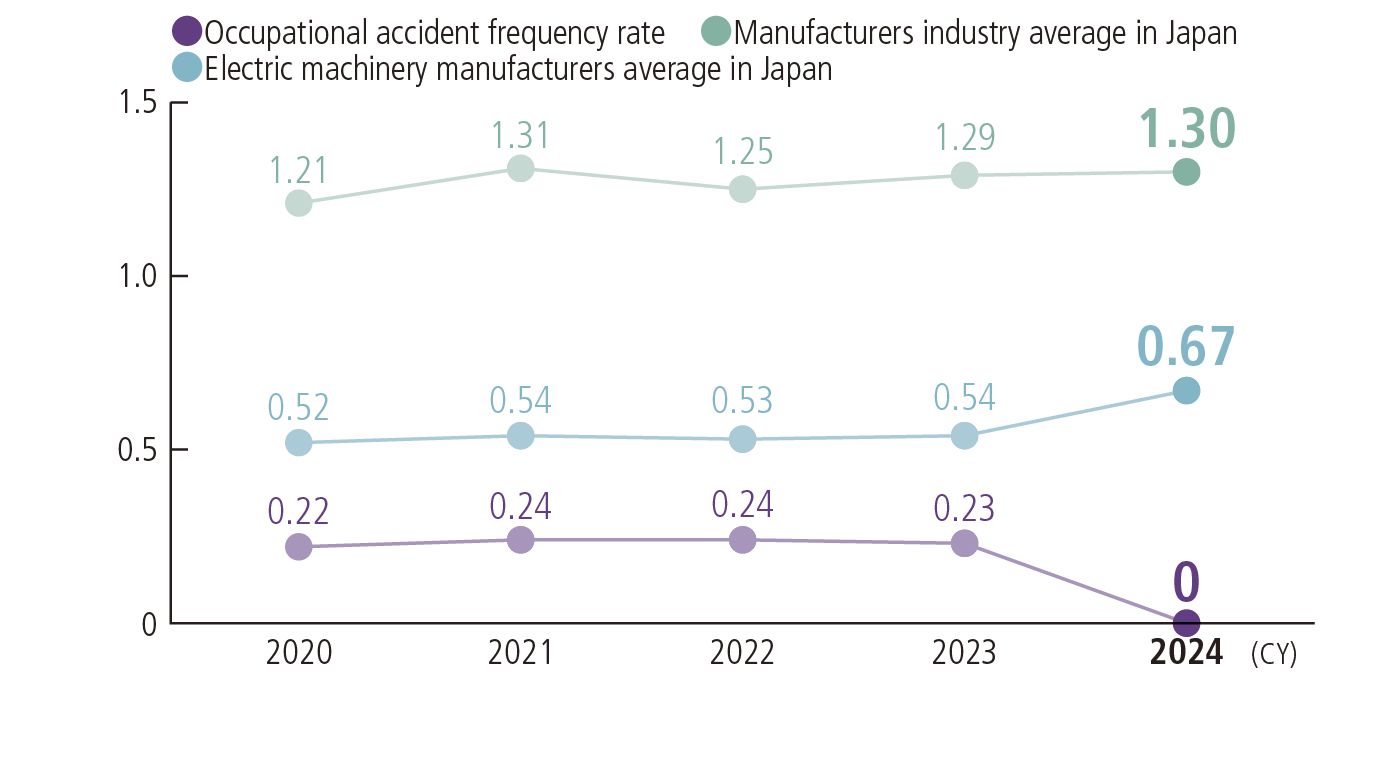

● Occupational accidents frequency rate

Injuries or deaths from occupational accidents per one million hours of work

Boundary: HD, SPE, GA, FT, PE, AS, IP

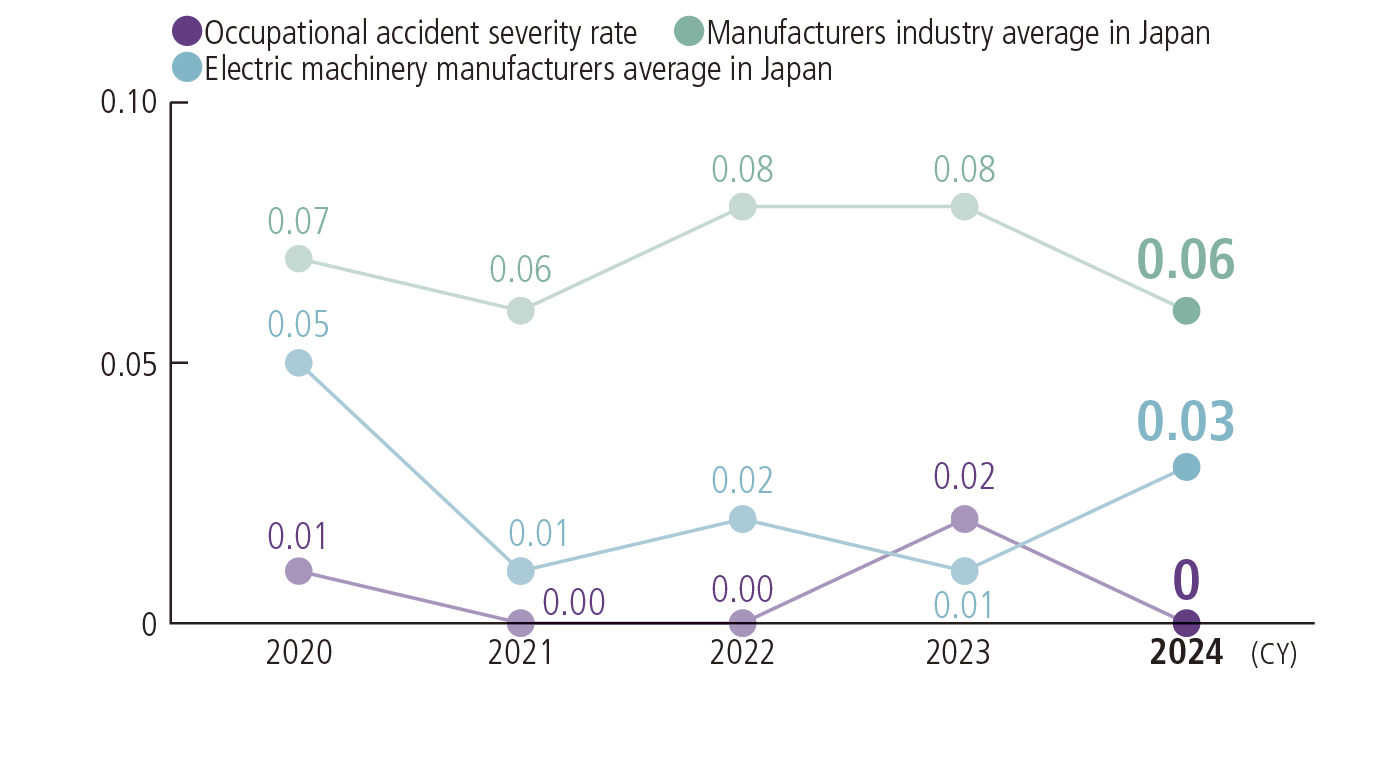

● Occupational accident severity rate

Days of work lost per one thousand hours of work

Boundary: HD, SPE, GA, FT, PE, AS, IP

Management of occupational accidents and incidents

We work to ensure employee safety and health in our business activities by implementing an occupational safety and health management system that conforms to ISO 45001. For development, manufacturing, equipment installation, and various other operations, we implement risk assessments and advance safety verifications to prevent work-related injuries and accidents. In addition, we ensure the operational safety of employees through independent training and qualification certification systems, including those related to the handling of heavy objects.

In the event of a workplace accident or incident involving an employee of a group company or partner company operating under contract, we use the Incident Report System, a proprietary accident and incident reporting system, to comprehensively manage every aspect of the response from receiving initial reports to analyzing the causes of the incident and completing subsequent corrective measures.

In the fiscal year ended March 31, 2023, we expanded this system to include group companies outside Japan as part of efforts to monitor occupational accidents and other incidents among all employees and advance reduction efforts globally.

Corrective measures and reports of accidents and incidents are mainly handled by the EHS administrator established in each company based on the responsibilities and authority defined in noncompliance and corrective measure rules. They are then reported to the EHS management supervisor. Corrective measures, including activities to prevent recurrences, are announced and rolled out across the Group as necessary, reaching beyond the departments they originate from.

Occupational accident prevention initiatives

● Safety patrols

The EHS management supervisor (an executive officer) and the EHS administrators of business operating companies conduct safety patrols. The patrols are being steadily rolled out to companies and worksites in order of priority to share understanding of problems and remove hazards before they cause accidents.

● Preventing serious occupational accidents and incidents through close call reporting

To prevent serious occupational accidents and incidents, we encourage our employees to proactively report close calls and take countermeasures in consideration of these reports. We also urge employees to feel free to report anything they have noticed or were troubled by that could lead to a close call. This information is shared internally to help prevent accidents.

● Strengthening occupational safety and health education

In addition to safety and health education for new hires, we provide education for employees when they begin work at a new facility2 and implement annual e-learning. Through such efforts, we work to ingrain the necessary knowledge, skills, and mindsets to avoid work-related accidents. We strive to ensure safety by providing various types of education based on roles and rank, as well as through unique educational and certification systems, such as those for workers who handle heavy objects.2 To promote and expand effective safety measures on the front lines, we are focusing on developing risk assessors and EHS experts.

2. Provided for group employees and partner company employees

FY2025/03 recipients of occupational safety and health education

| Course name | Participants | Course content | Number of participants (persons) |

| Safety and health education | New graduate and mid-career hires of the SCREEN Group in Japan (HD, SPE, GA, FT, PE, AS, IP, BEX) | Health and safety basics, SCREEN’s health and safety activities, and legally defined duties of consideration for safety, self-health maintenance, and best-effort obligations | 363 |

| Follow-up safety and health education3 | New graduate and mid-career hires of the SCREEN Group in Japan (HD, SPE, GA, FT, PE, AS, IP, BEX) | Excerpts from health and safety training for new employees | 242 |

| Foreman education | New foremen of the SCREEN Group in Japan | Legally stipulated health and safety-related content | 12 |

| OHSMS risk assessor education | OHSMS risk assessors of the SCREEN Group in Japan | OHSMS-related risk assessment details and methods | 51 |

| EHS expert development training | New EHS experts of the SCREEN Group in Japan | Explanations from external speakers on EHS management systems (EMS, BCMS, OHSAS), RBA, and other topics (elective subject system with qualifying test) | 52 |

| EHS general basic education3 |

Directors and all employees of the SCREEN Group in Japan | EMS activity basics | 3,892 |

| 3. e-learning | |||