The most ideal direct imaging equipment

for various semiconductor package substrates

by starting with FC-CSP

NEW ReleaseLarge sizes

We also offer models* in sizes of up to 32 inches that retain the exposure quality of smaller sizes. These variants are also suitable for use in applications that involve metal masks that demand high render precision and large-format materials such as probe circuit boards.

*LI-7F-L

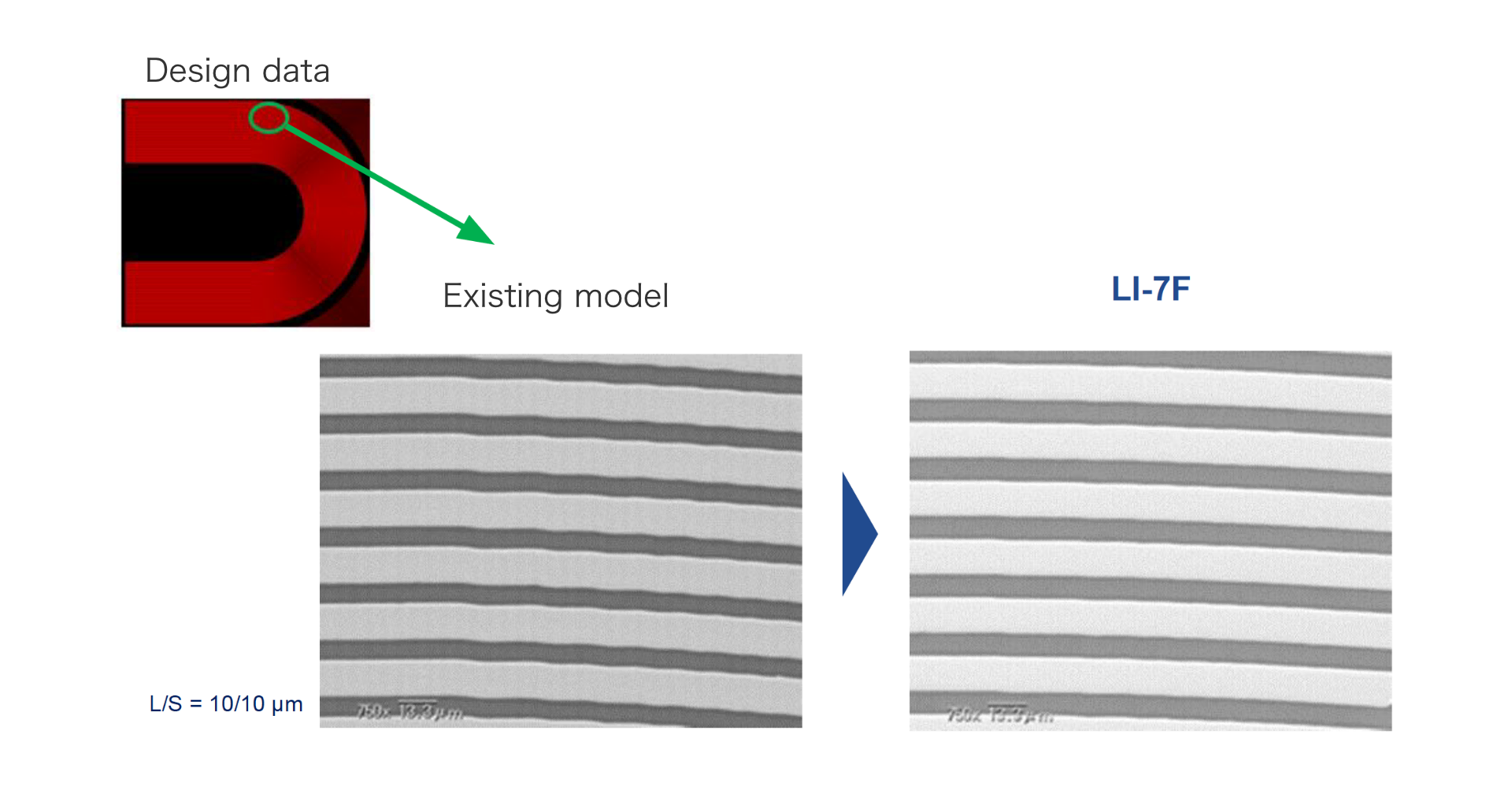

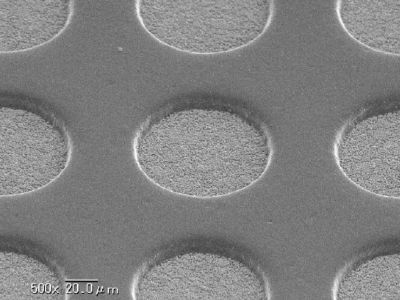

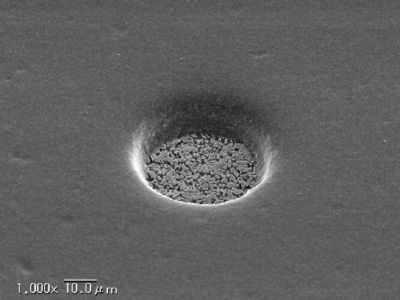

The finest imaging quality

Effectiveness at higher resolution

Curve pattern getting smoother

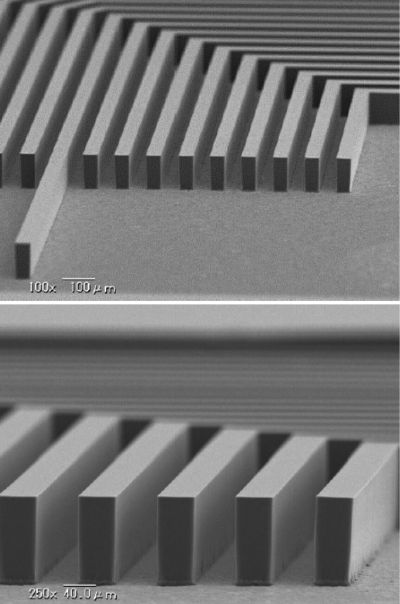

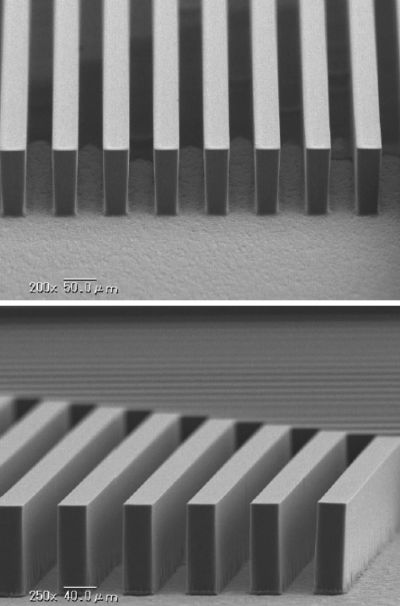

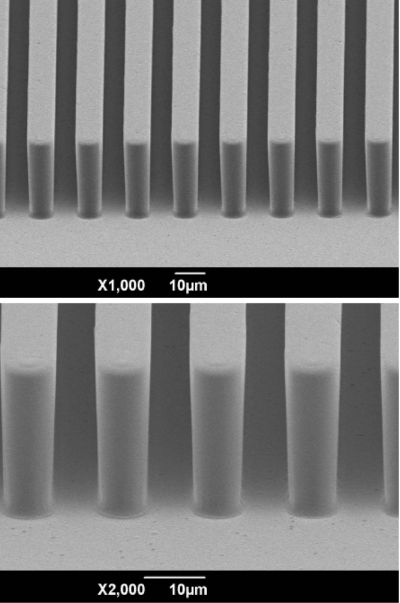

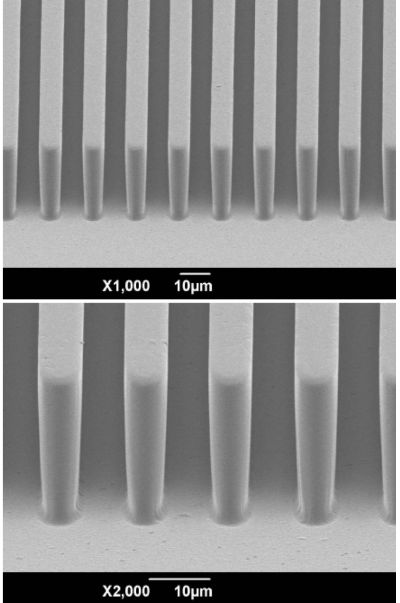

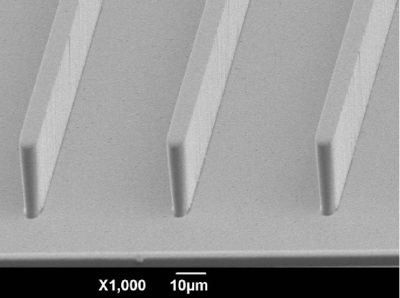

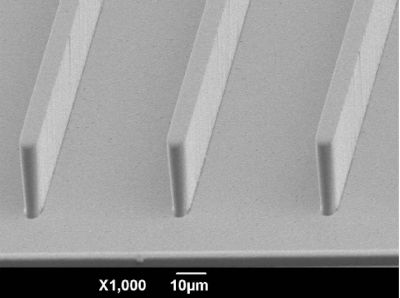

Samples

-

L/S = 50/50μm

*This is a limited sample exposed under the conditions, whitch specified By SCREEN

-

L/S = 40/40μm

-

L/S = 8/8μm

*This is a limited sample exposed under the conditions, whitch specified By SCREEN

-

L/S = 7/7μm

-

8μm line

*This is a limited sample exposed under the conditions, whitch specified By SCREEN

-

7μm line

-

SRO = 80μm

*This is a limited sample exposed under the conditions, whitch specified By SCREEN

-

SRO = 40μm

New function! Design matching, enabling highly accurate alignment!

Can be used even if it is not a Point symmetric figure and Any pattern can be used as an alignment mark.

3 wavelengths LED technology

3 wavelength LEDs technology

Precise quality control by flexible wavelength mixture technology

3 wavelength LED technology

Easy to optimize best condition for every material with exposure power control

Various alignment method

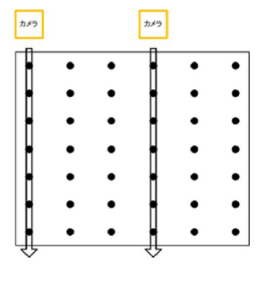

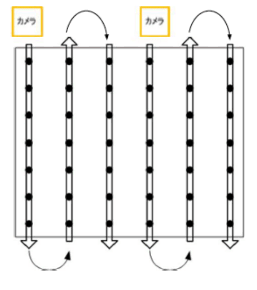

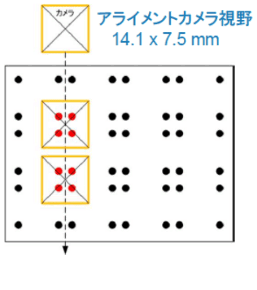

Scan alignment

-

マーク撮影時に

ステージを止めない

-

ステージの往路・復路で

マークを撮像する

-

隣りのマークもカメラ視野に

入れる場合一度に撮像

Further speed-up will be possible by using simultaneous reading of neighbor marks

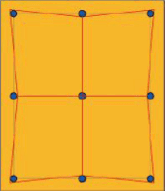

Alignment algorithm

-

Global

Rectangle

-

Multiple points & Whole area

Linear

Curvw

-

Mark sharing

Sharing alignment mark

-

Multiple points & Individual area

Rectangle

Linear

Variety of algorithms achieve optimal alignment

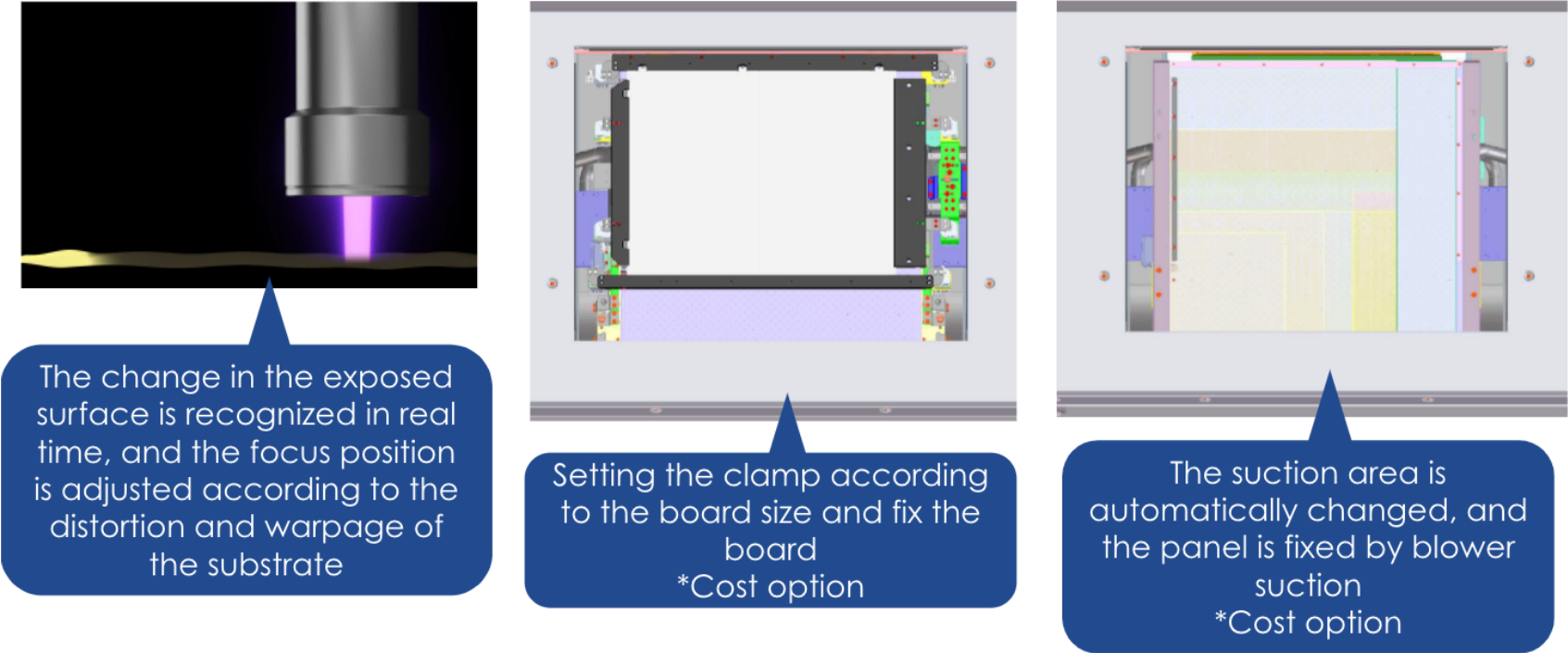

Auto-focus function

Auto-focus and measures for panel warpage

- Auto-focus

- Mechanical clamping unit

- Auto switching for suction area

Supporting board warpage response with auto-focus function and optional mechanism

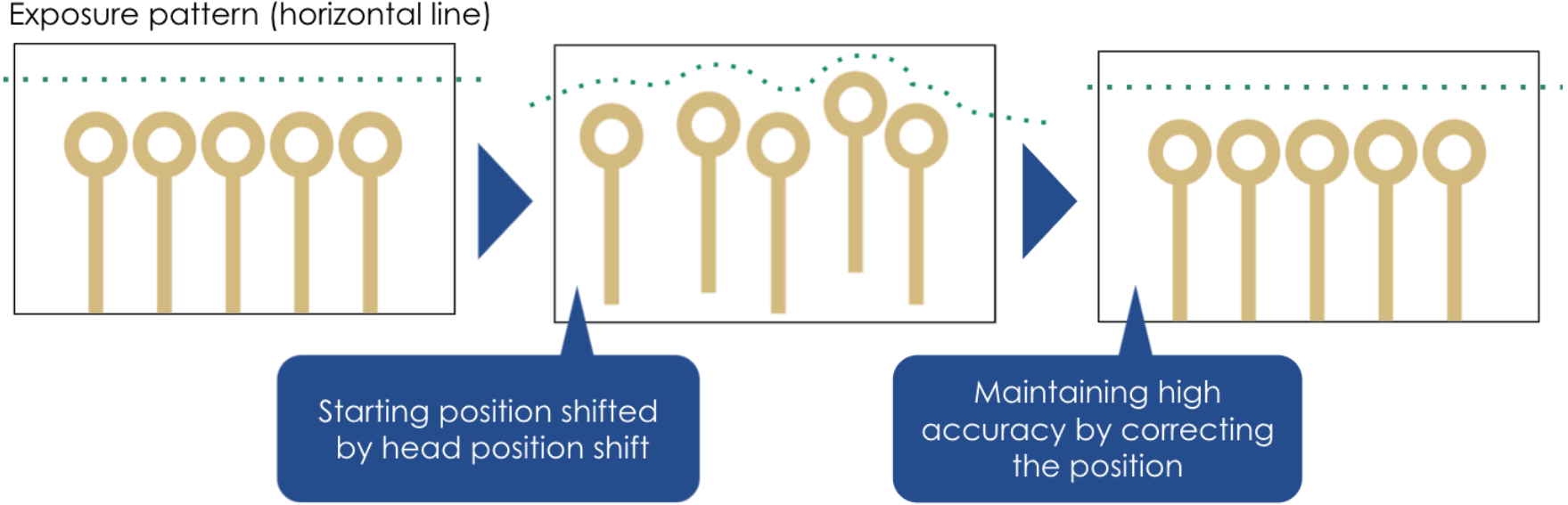

The idea of automation

- Start

- Change over time

- After calibration

*Calibrate the alignment camera in the same way

Achieving accurate patterning without stopping machine by manual adjustment

The idea of automation

Barcode function

-

Single side auto type

-

Double side auto type

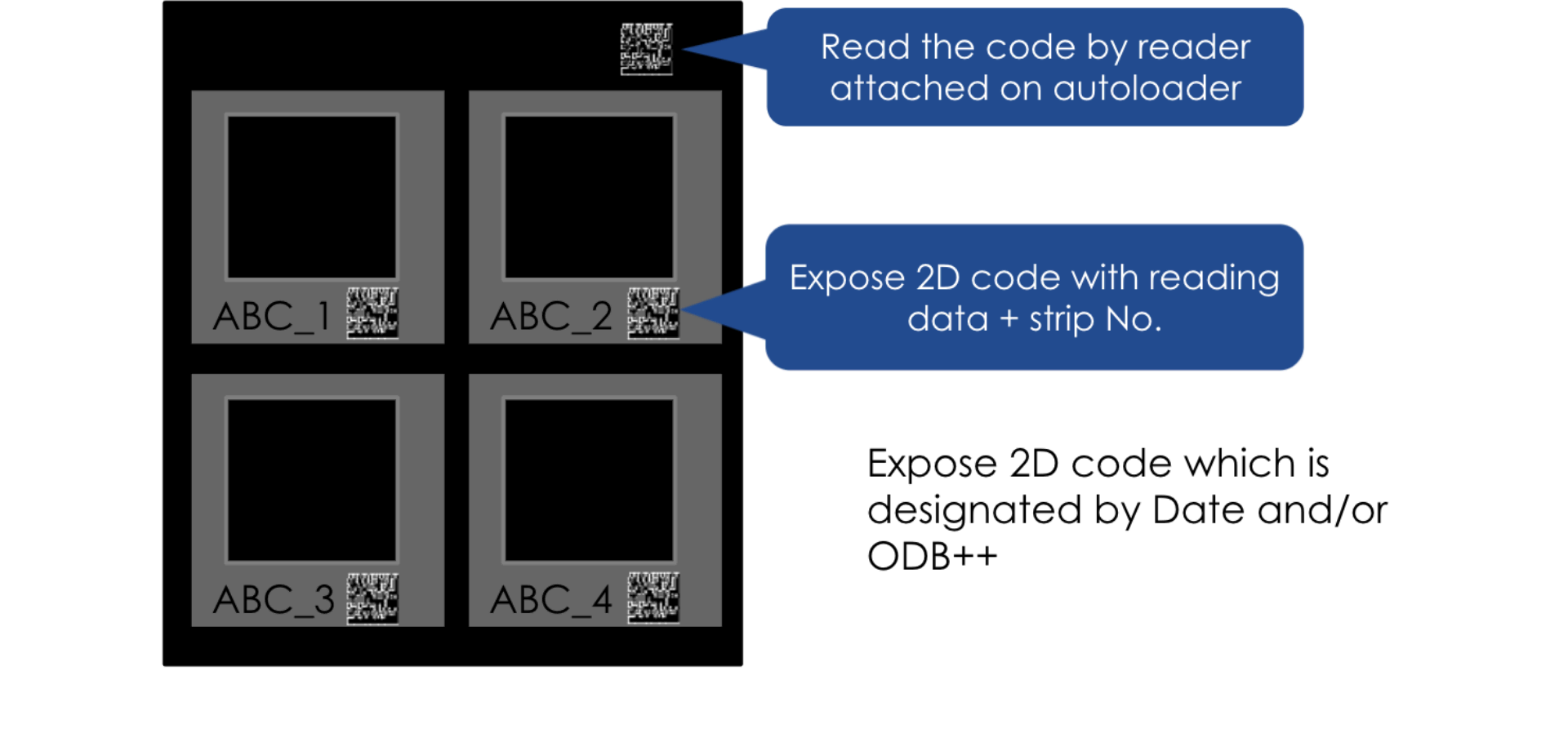

Traceability control

Compatible with various barcodes

-

1D code

-

2D code

Achieving high traceability of the entire manufacturing process

2D code imaging function

2D code can be added not only to the board but also to each piece

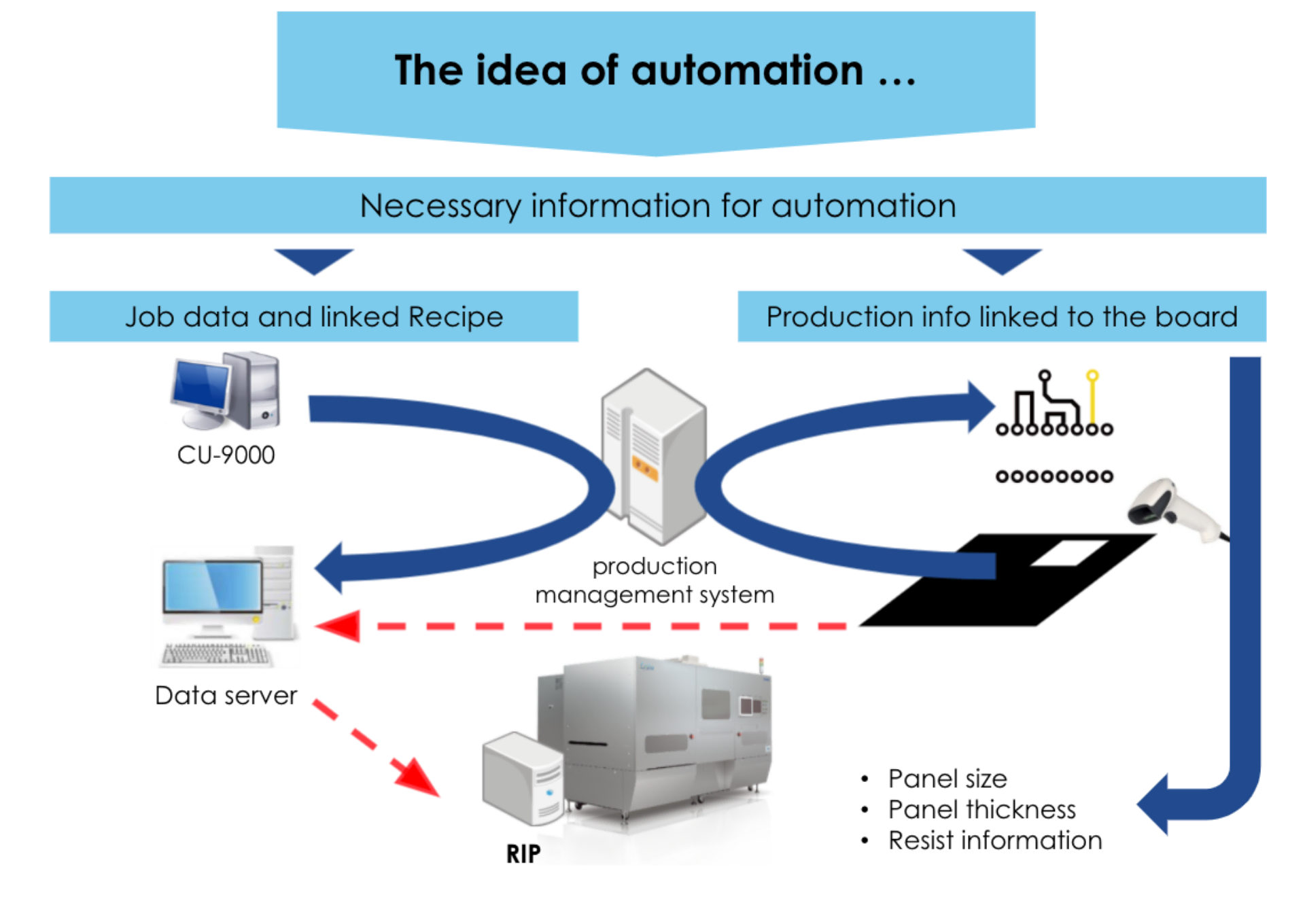

Automation

The idea of automation ...

Necessary information for automation

Job data and linked Recipe

Production info linked to the board

Achieving the idea of automation in exposure process