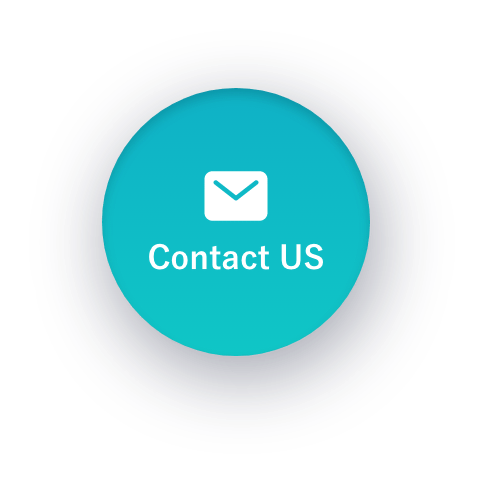

Gate to the Infinity

Series best positional accuracy and stability

Image positional accuracy has been dramatically improved by structural optimization design.

It delivers a sophisticated and high level of performance with stability that will be required to produce the future ICS.

-

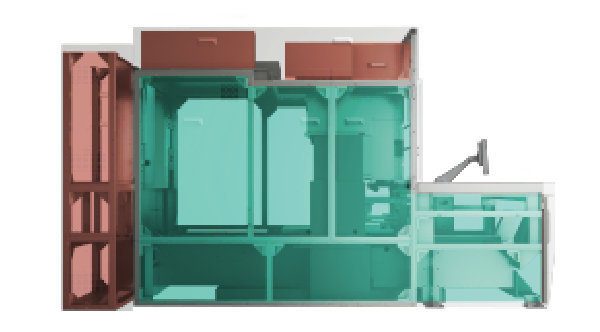

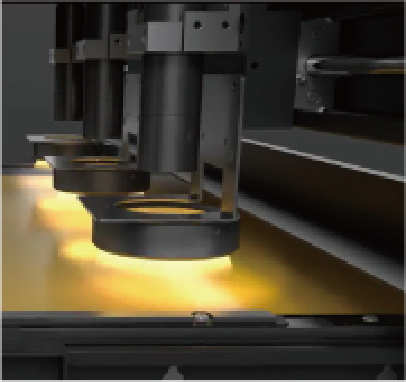

01Temperature control

A cooling mechanism has been added to optimize temperature management inside the system. Furthermore, improving the cooling efficiency drive unit and cutting off heat conduction to the main body base, provide improvment in imaging positional accuracy.

-

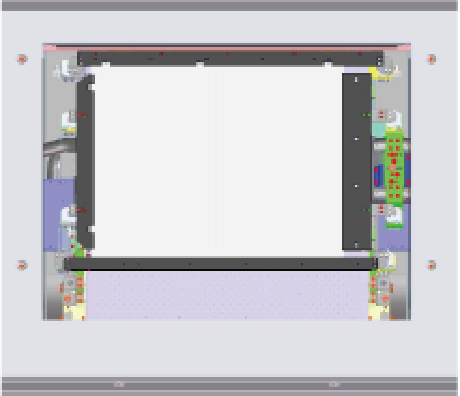

02Renewed main body platform

The rigidity of the main body frame has been significantly improved compared to conventional models.

In addition, the positional relationship of the exposure head, alignment unit and other hardware have been revamped to create an optimal platform.

-

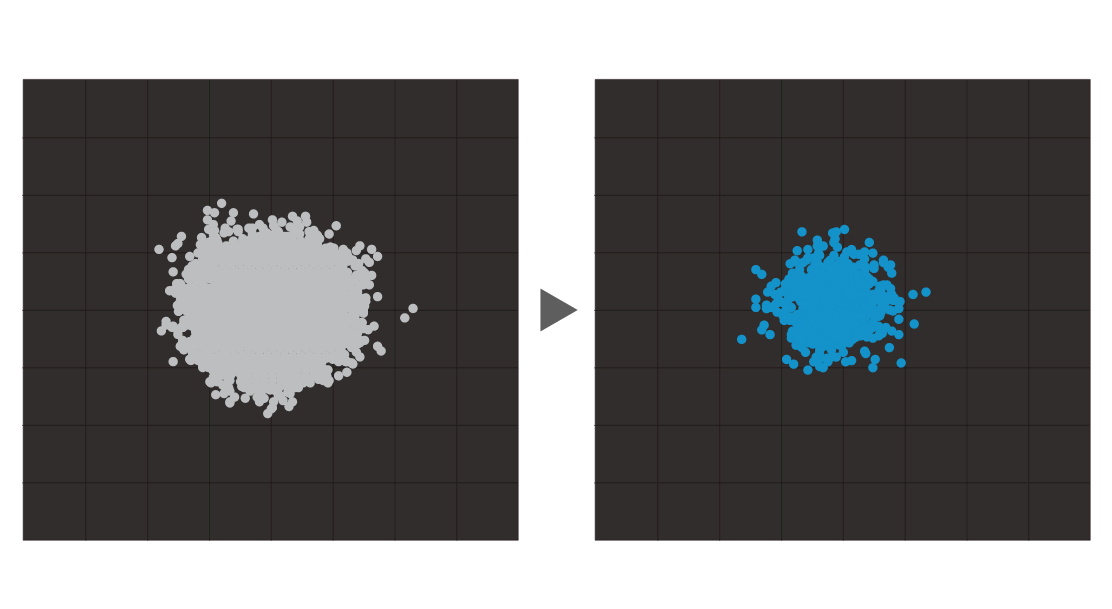

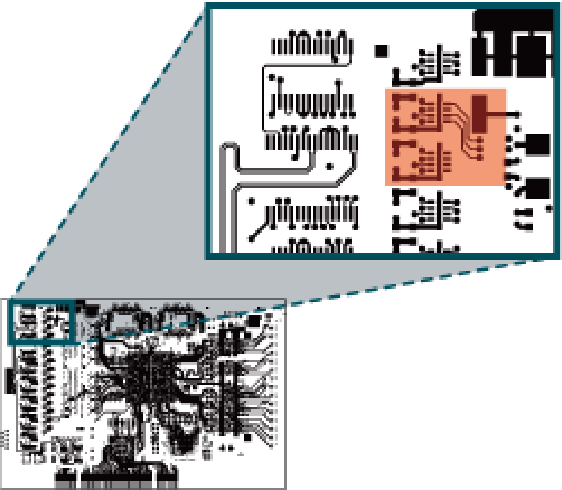

03Constant calibration

Head calibration is performed while the operator exchanging boards, which consistently delivers high accuracy with excellent productivity.

Corresponds to board warpage

It provides stable imaging quality with various mechanisms that can automatically handled for warpage regardless the type of board.

Autofocus

Mechanical clamp (option)

Automatic suction area switching (option)

Alignment processing

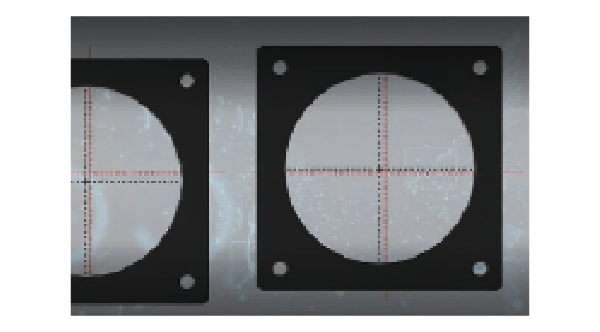

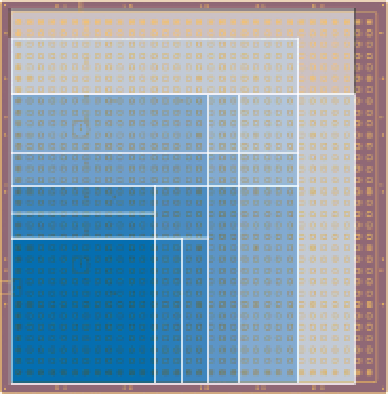

The Ledia 8 is equipped with a variety of alignment functions to meet the increasing demands for alignment accuracy requirements.

Design matching function (option)

Scan alignment method

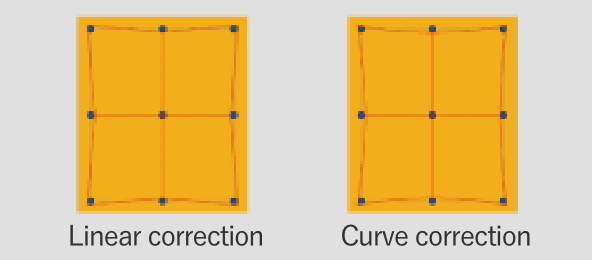

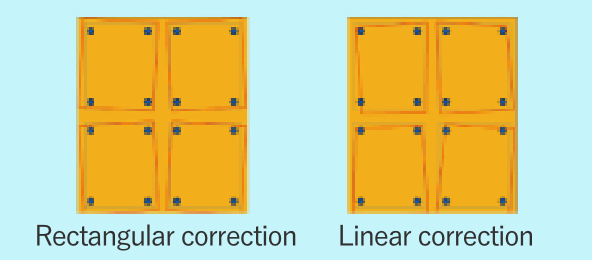

Distortion correction

By area

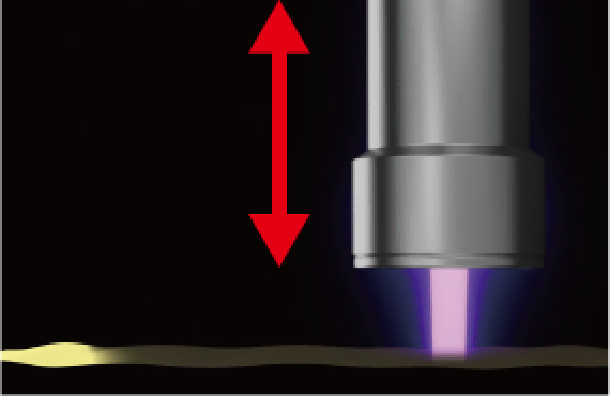

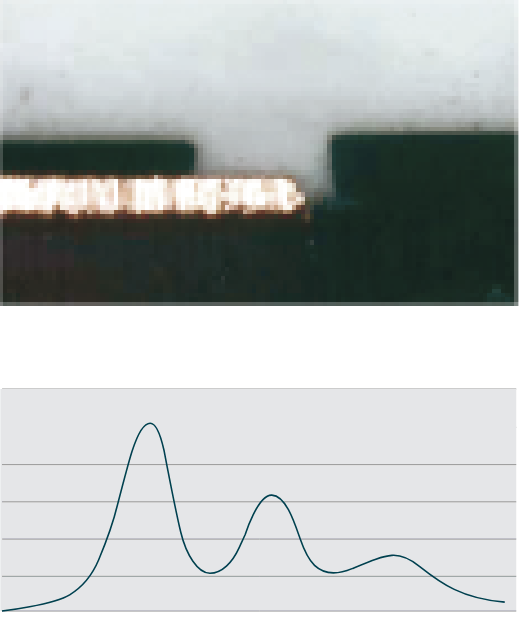

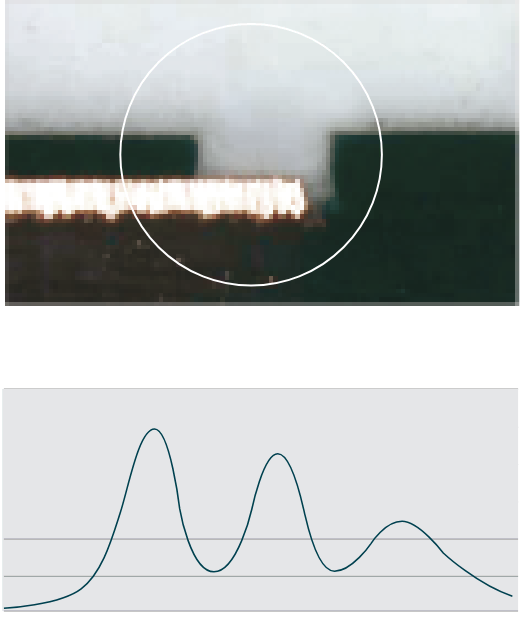

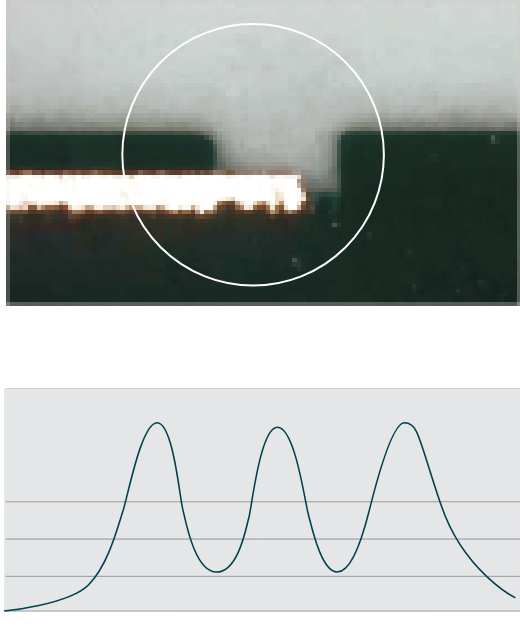

Three-wavelengths

The cross-sectional shape of the photosensitive material can be controlled by adjusting the wavelength mixing ratio.

Three-wavelengths LED light source

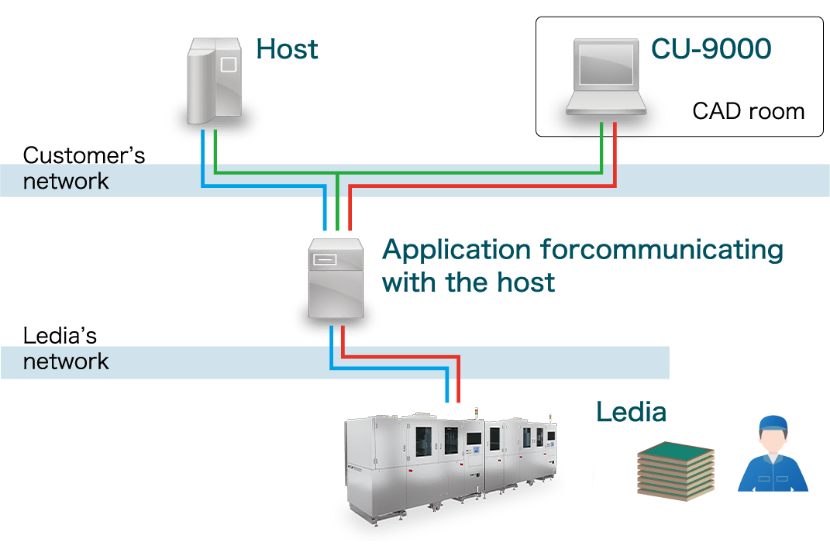

Automation and online-host support (SECS/GEM)

Online-host setup