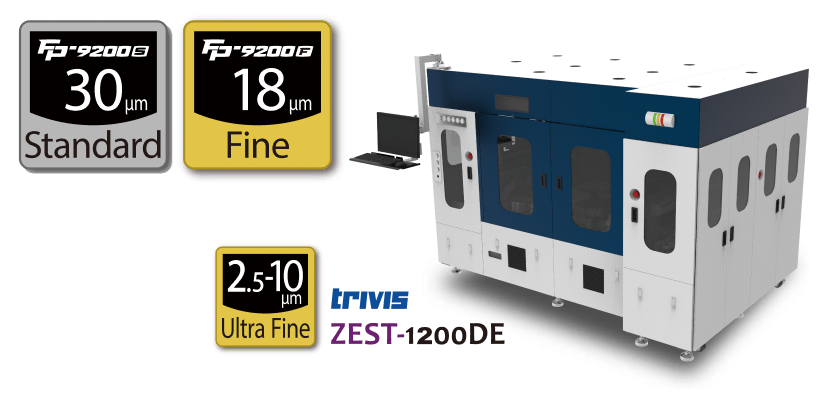

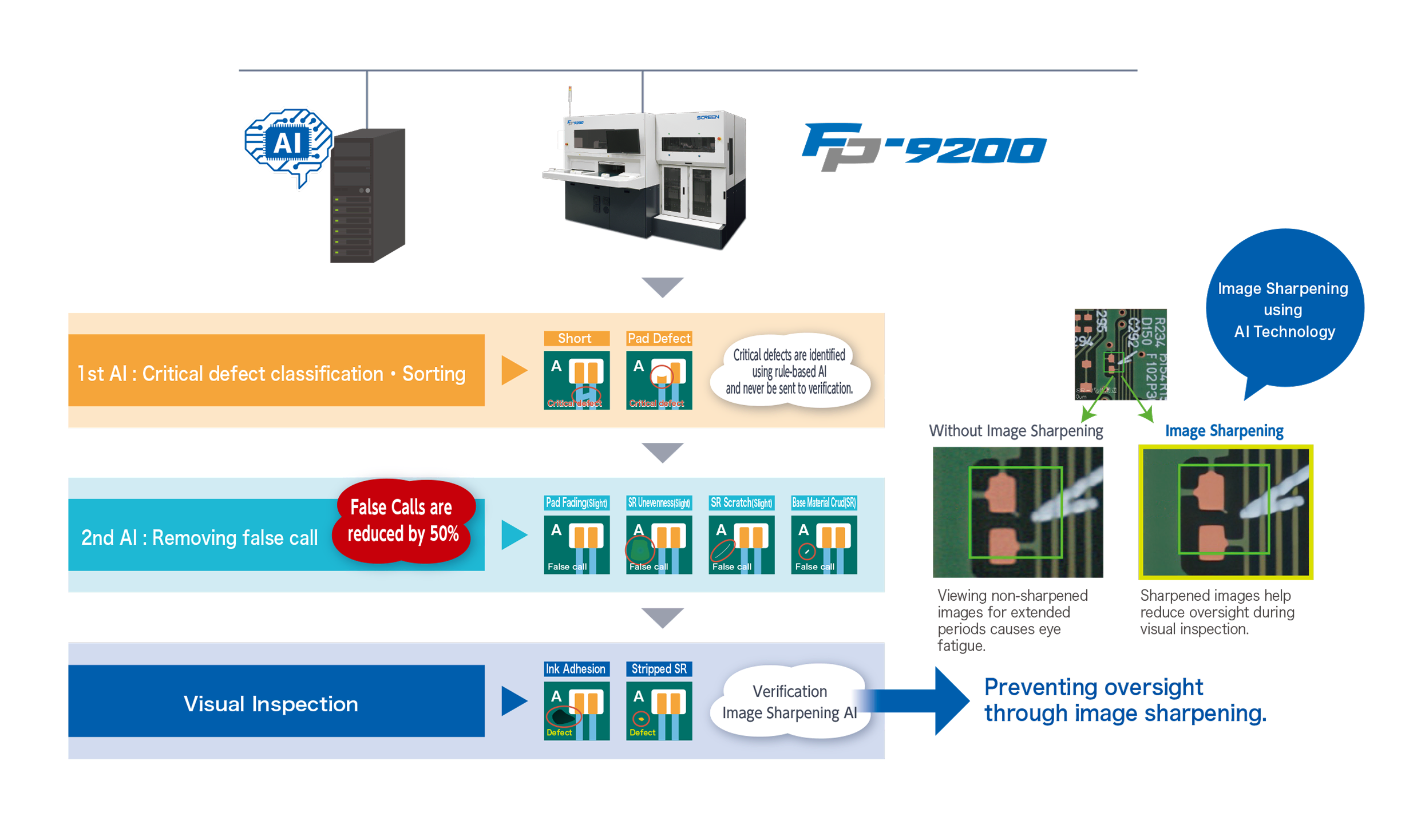

Equipped with a new inspection function for improving detection capabilities,

which significantly reduced false calls.

NEWEquipped with a new AI function with Zero Risk of Missing Out.

Fast and reliable, New era of AI×AVI has come.

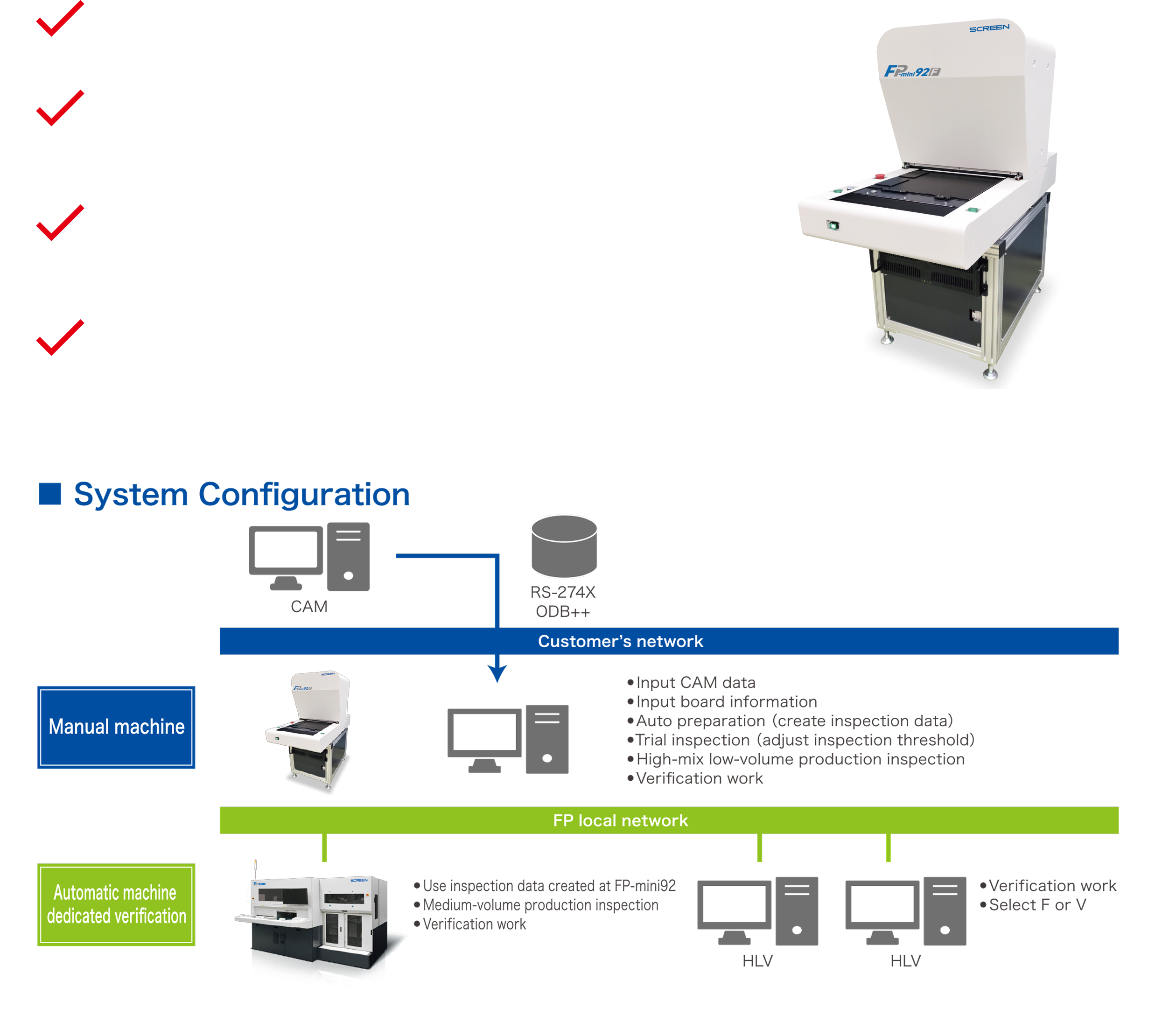

NEWMulti-purpose visual inspection system FP-mini92

Applicable for boards that are difficult to convey automatically and for high-mix low-volume production (such as modular, non-standard shaped, FPC and ceramic boards).

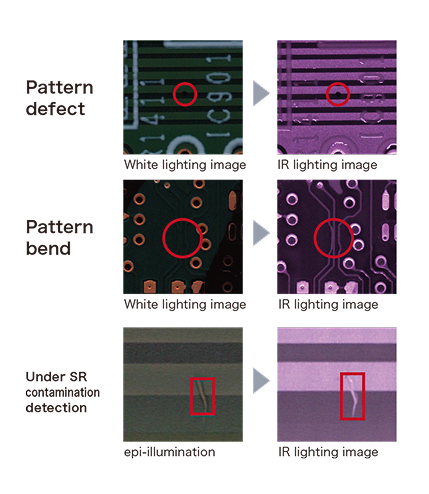

Improved Detection Capability

IR light source

One of the characteristics of IR light source, which transmit easily through SR and reflect on the surface of copper. Therefore, IR light source can sharply display pattern on deep color SR board inspection, where standard

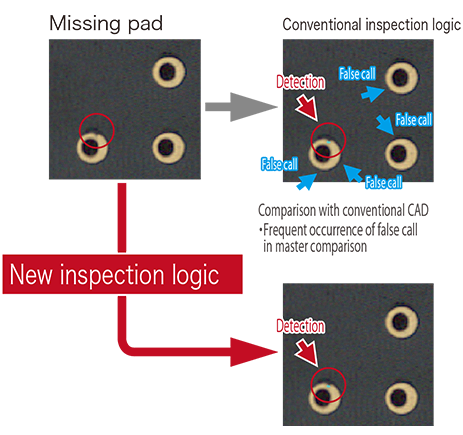

■CMeT Circle Major extraction Technology

Change point detected based on surrounding shape! Detection without false call!

CMeT inspection logic newly developed for responding to the requests for industrial circuit board inspections

Millimeter wave radar board inspection

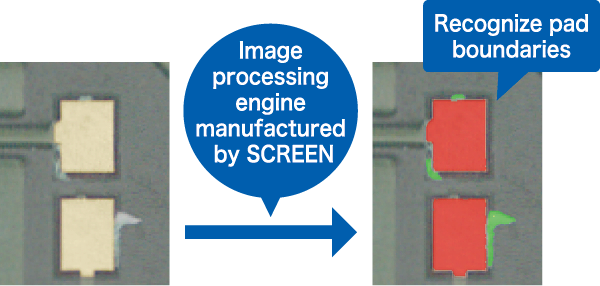

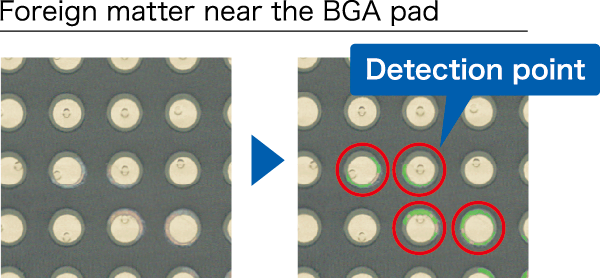

For stable detection of foreign matter around the pad

Since the boundary of the pad can be recognized in real time, it is possible to inspect to the very limit of the boundary.

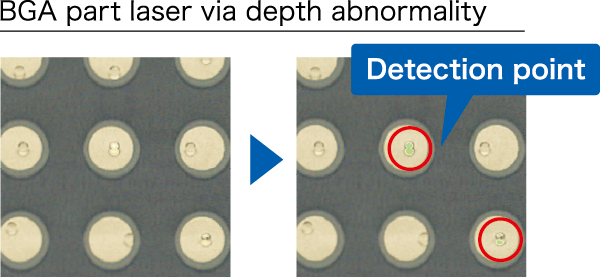

BGA pad inspection is also a handy thing

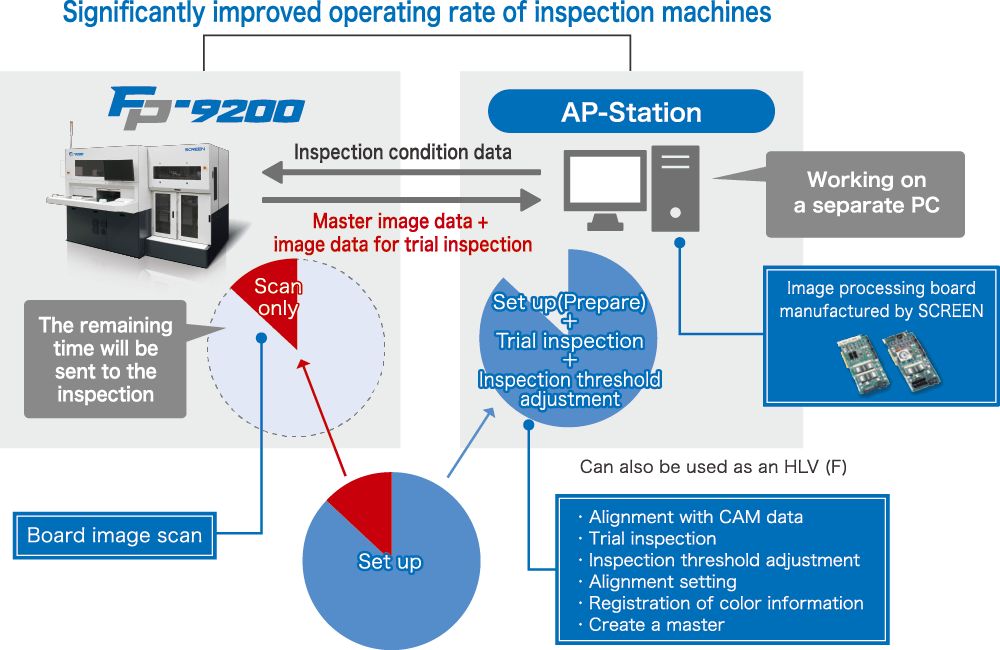

The equipment utilization rate is greatly improved if was equipped with AP-Station.

When setting up a new product number by using AP-Station, the main device scans the board, and other set-up preparation such as trial inspection, and inspection threshold adjustment are performed on a separate AP-Station. The operation rate of equipment can be greatly improved.

AP-Station is useful tool for trial inspections and false calls reduction adjustments, when changing lots.

Easy and high-speed setup with auto-preparation function

Easy operation for automatic setting of setup and parameter adjustment

"Auto prepare" allows you to automatically set up from board image scanning to master generation. "trial inspection" allows you to perform repeated tests without transporting the test board. "automatic false calls removal" assists in adjusting inspection parameters. It provides a much easier and faster setup than our conventional model.

Good board transferPrepareBoard transferInspection parameter adjustment

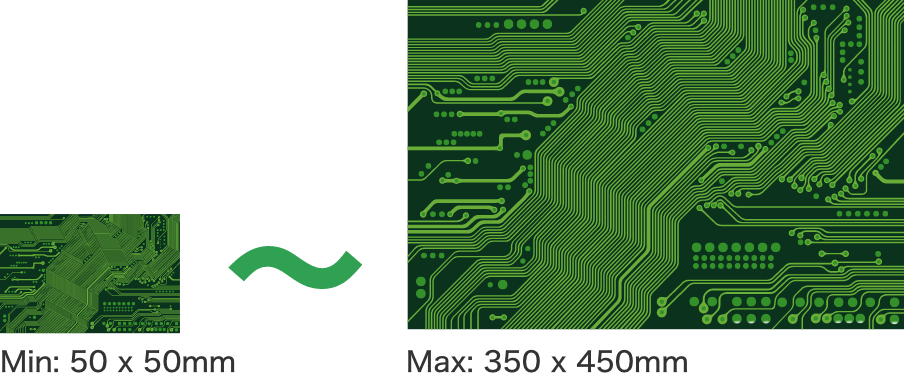

Even fine machines can handle large size boards.

Even fine machines can handle large size boards.