Just right, there it is.

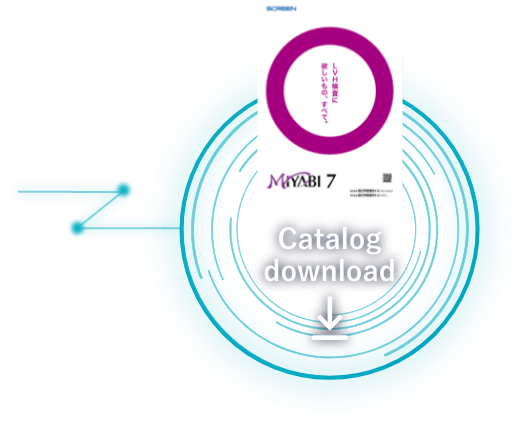

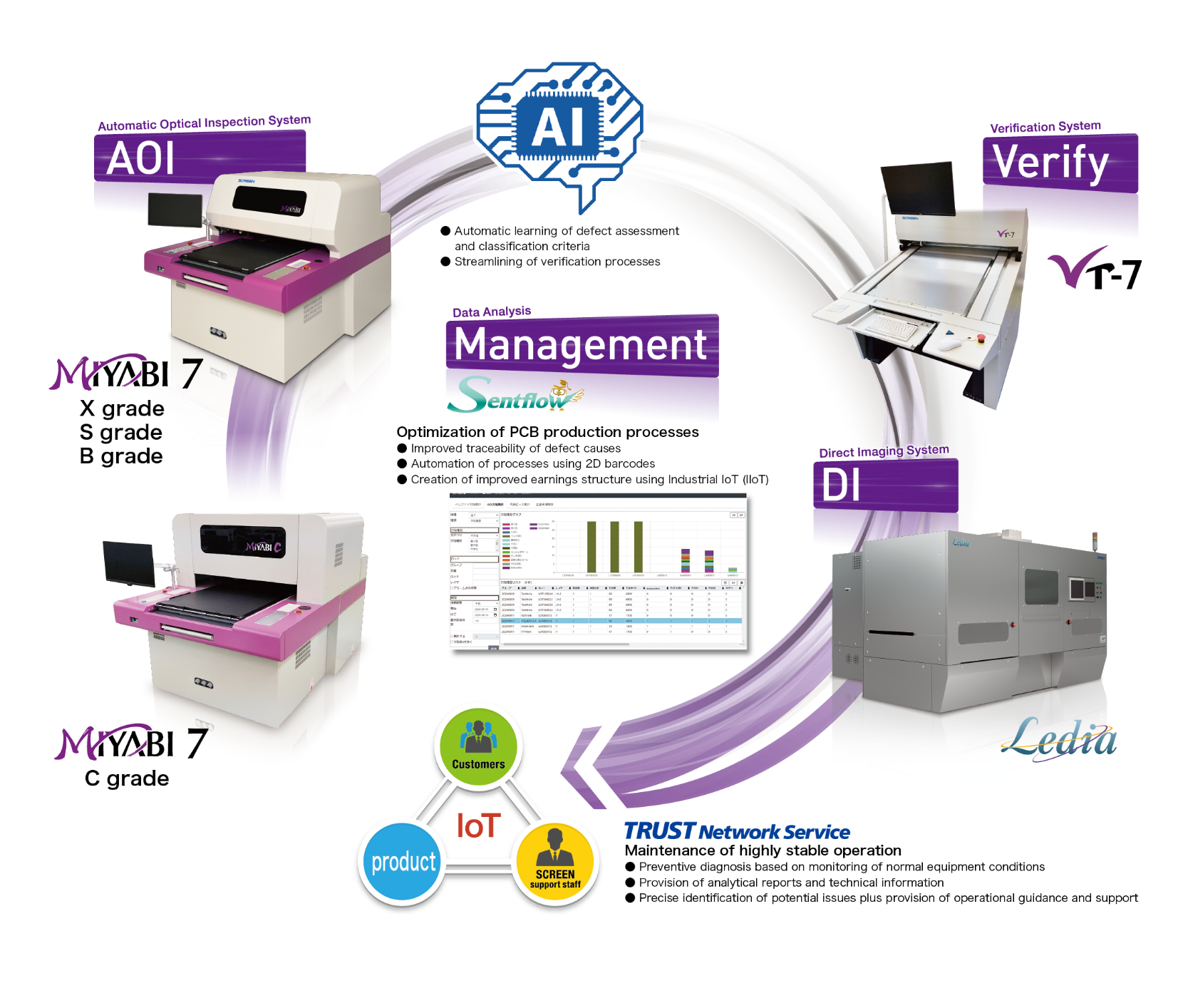

An equipment line-up to support a wide range of applications

The addition of circuit inspection to the X-grade makes it possible to inspect the high-value-added boards with outstanding throughput. Choose from four different grades to meet your application requirements such as thick copper substrates, HDs for antenna or sensor modules, and package substrates for automotive ICs.

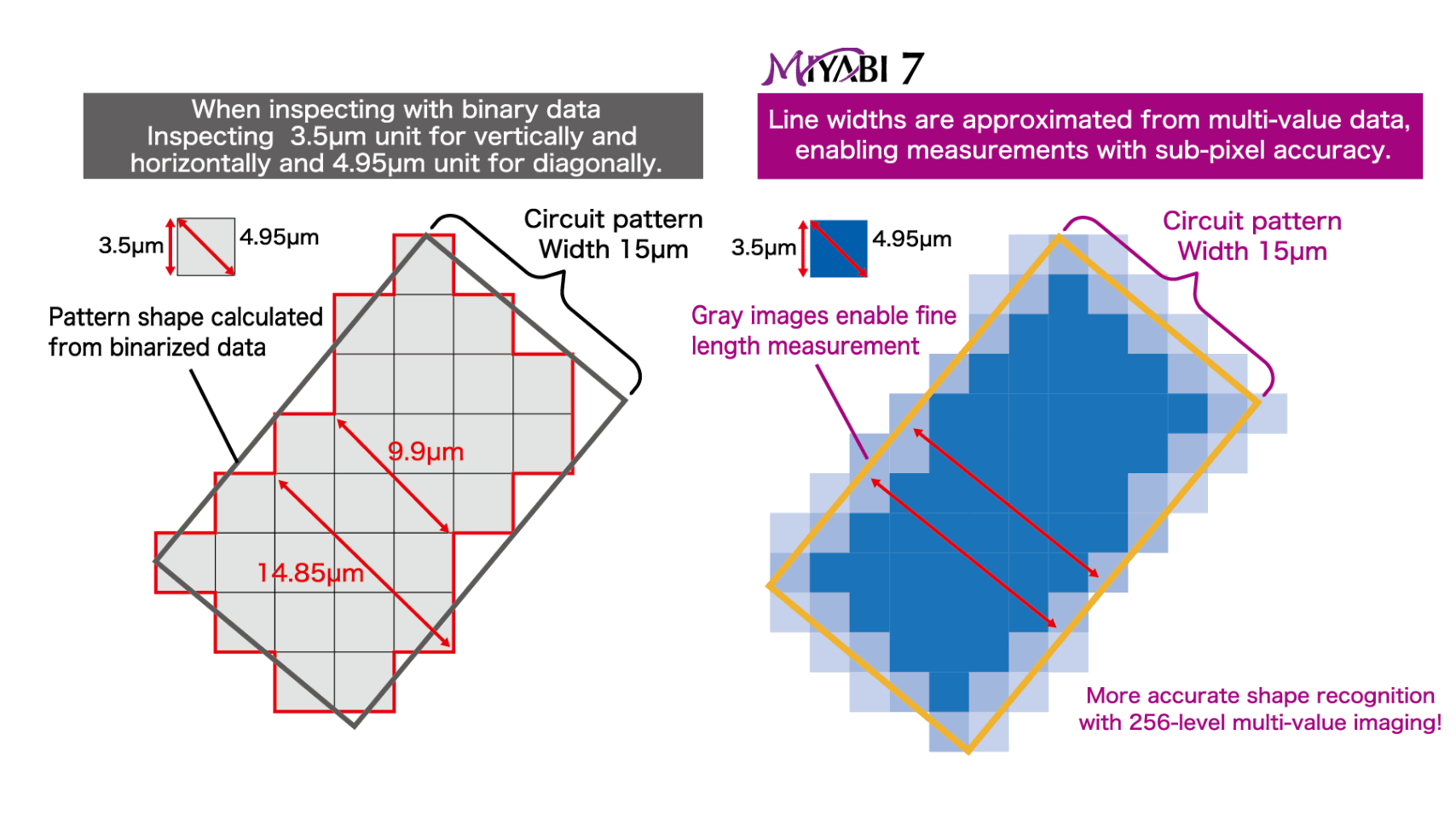

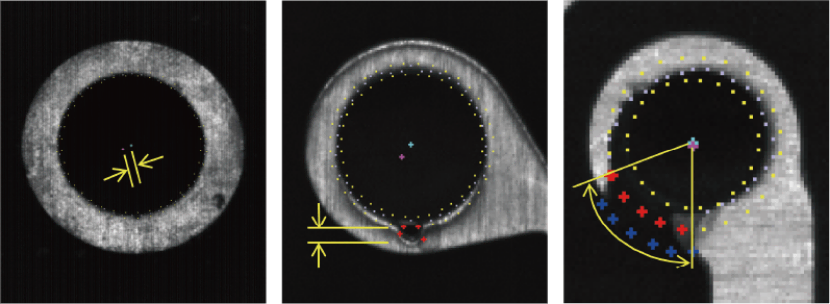

High-precision length measurement inspection with multi-value images

In addition, not only the binary image of comparison and DRC inspection, but high-precision inspection at the sub-pixel level is possible by performing line width measurement inspection based on multi-value images. It is now possible to inspect for gradual chips and protrusions that were previously difficult to detect while maintaining the number of calls to a minimum level.

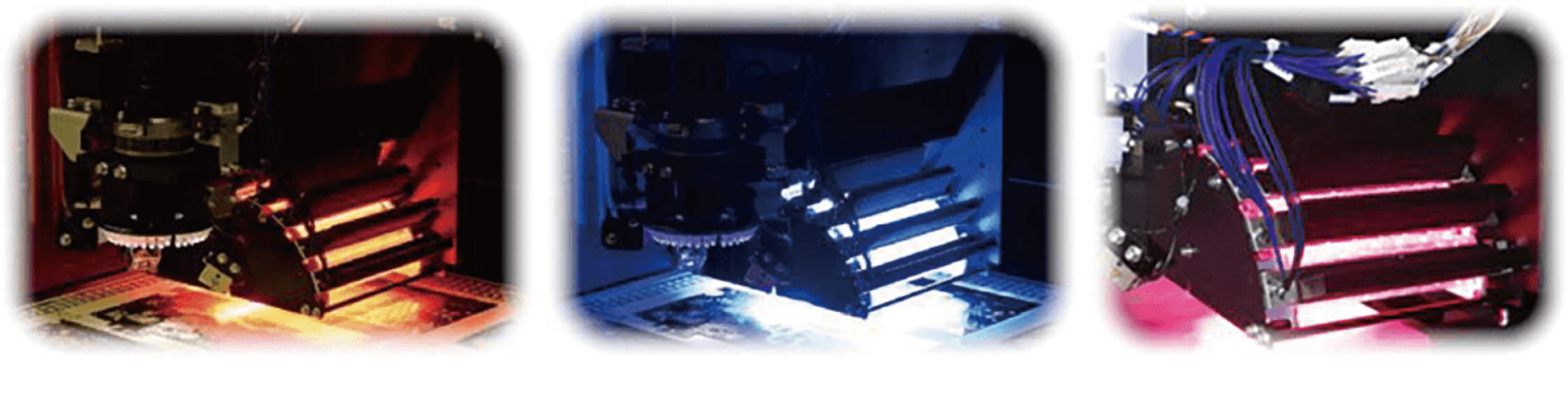

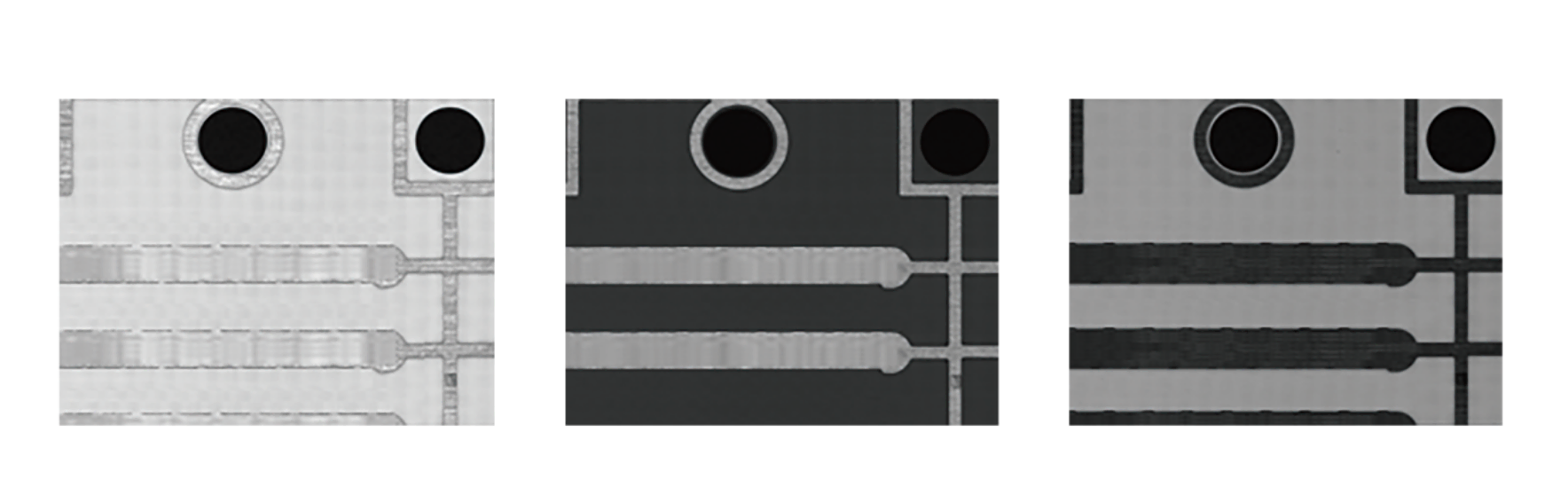

Corresponding all kinds of substrates and materials with line dome lighting.

The 9-axis (4-axis for C grade) polygonal line dome lighting allows optimal light intensity adjustment according to the various surface treatments, materials, and processes. The pattern can now be easily recognized and achieve good inspection results where difficulties in ensuring contrast between the pattern and base material in the past.

Reduces transparency of FPC backside

Corresponding for white substrates

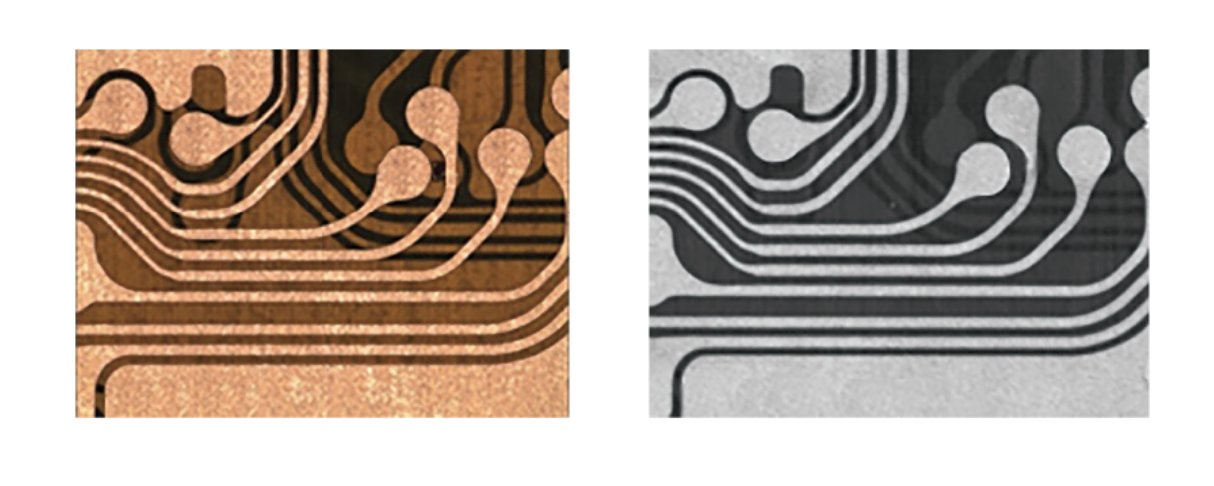

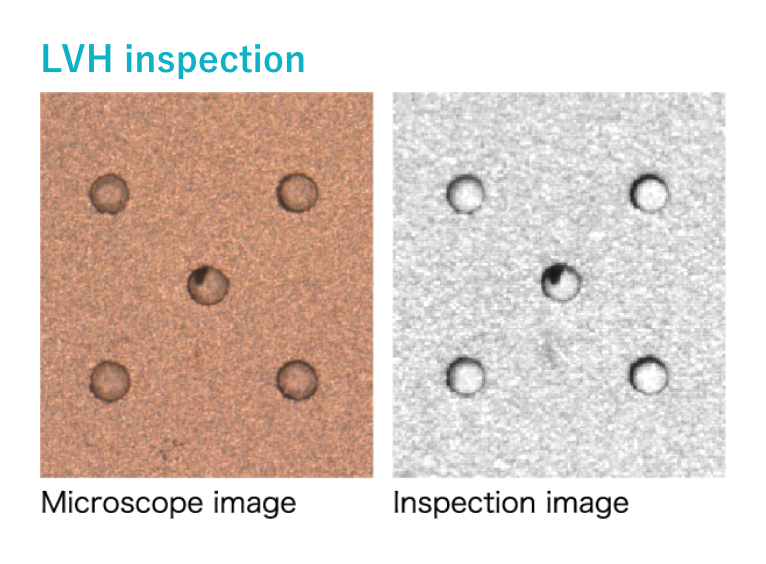

Corresponding both circuit patterns inspection and LVH inspection

It is also equipped with unique logic for LVH testing.

MIYABll platform can detect current market demand with high accuracy, which has been increasing for inspection via diameter measurement and abnormalities, as well as hole misalignment, and roundness. In addition, It can also be used as a dual-purpose machine since it is possible to inspect circuit patterns and LVH at the same time.

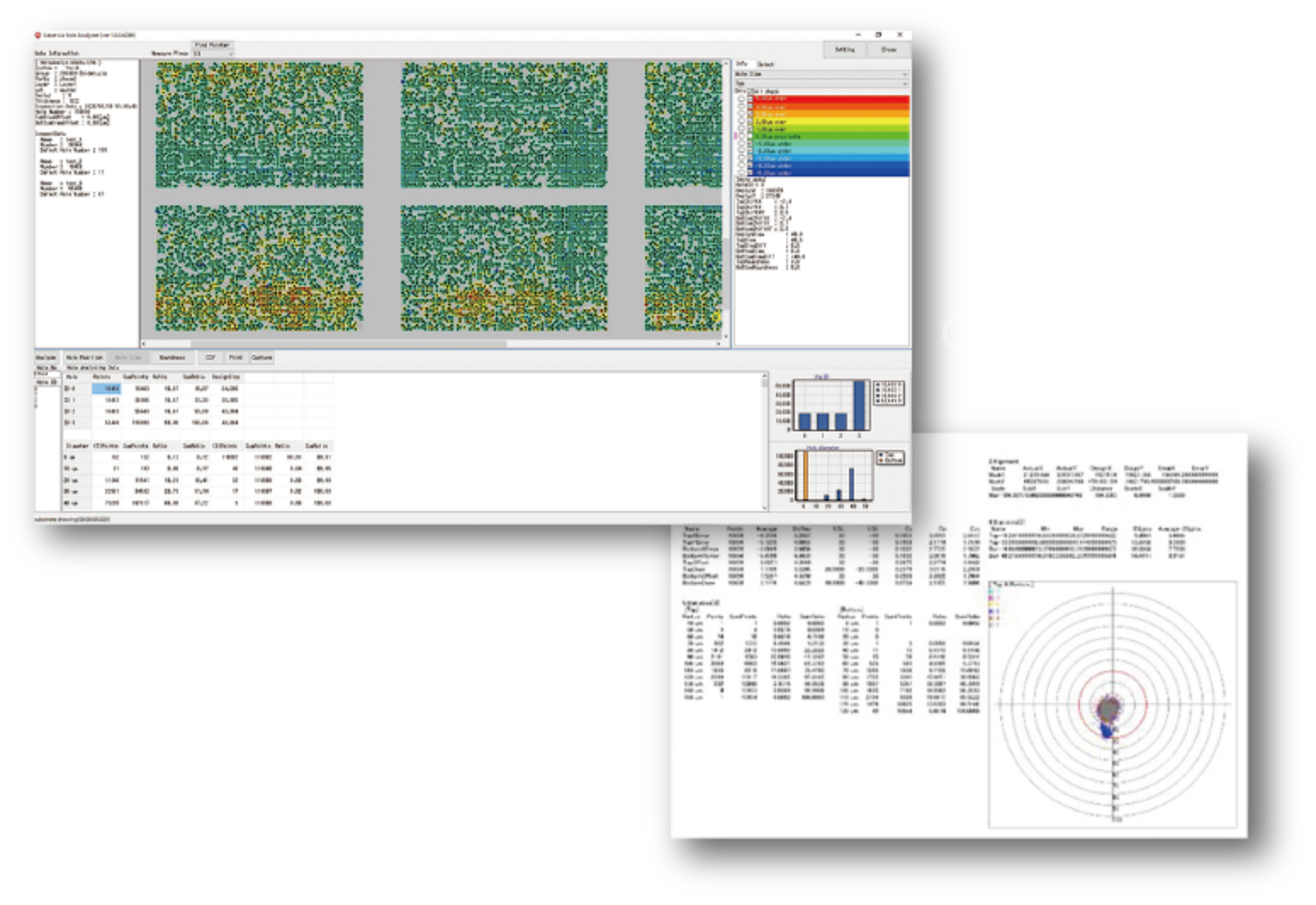

Enhancing analysis functions

Specially developed analysis tool software enables various analyses to be performed for each board. Proprietary software tools enable thorough analysis of individual boards. Along with CSV files, analysis reports can be output as images for printing, enabling immediate use.

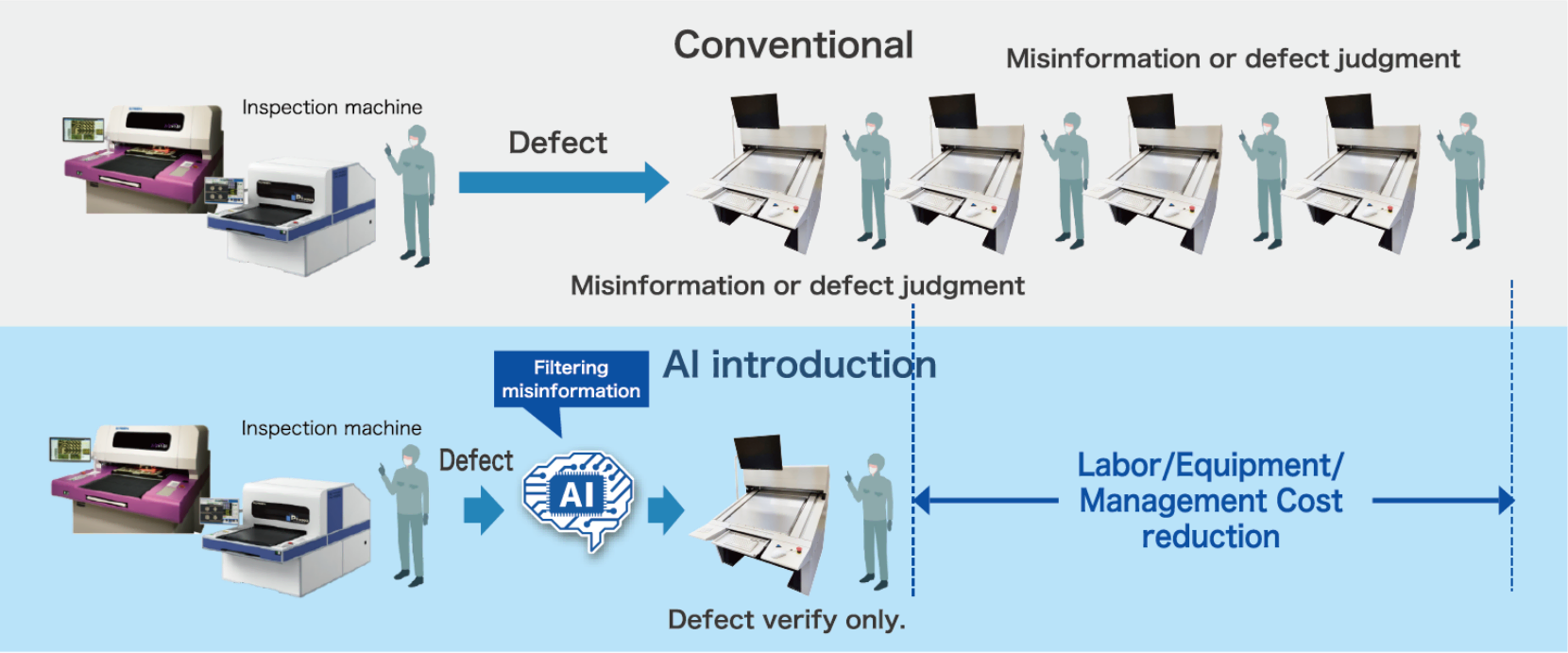

Using AI to reduce confirmation time and manpower!

In recent years, PCB manufacturing sites have been facing labor shortages and a demand for labor-saving measures to reduce costs. SCREEN can automatically apply filters to the detection results of our in-house developed Al system inspection equipment. The number of minimum defect candidates handed over to the verification process, which is already reduced in advance by filtering out false calls. This significantly reduces manpower and improves process throughput.

Connection with exposure and data analysis systems boosts processing performance

Smart support for efficient operation of inspection system

The CU-9000 is a setup station that enables rapid transfer of design data from CAM processes to inspec- tion systems.

It is equipped with a wide array of functions ranging from batch setup of multiple layers to automatic extraction of signal lines, pad sections and other areas requiring particularly strict inspection.

The CU-9000 maximizes the performance of inspection systems, allowing them to keep pace with increas- ingly demanding inspection requirements.