Coater/Dryer RT-R series

This roll-to-roll coater/dryer unites outstanding coating technology with high-precision WEB transfer technology. Thick film coating of high viscosity material to thin film coating of low viscosity material is possible roll-to-roll.

Suitable for R&D or pilot production of various rechargeable batteries, such as all-solid-state batteries.

Features

- Applying high-precision coating technology cultivated in display manufacturing equipment.

- Delivers precision coating of low to high viscosity material.

- For drying, in addition to the usual hot air furnace, a push-pull method that enables energy-saving and high-efficiency drying can also be installed.

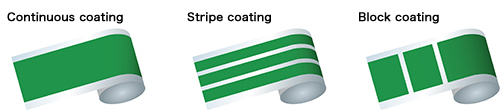

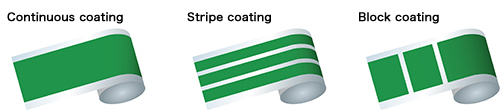

- In addition to continuous coating, stripe coating and block coating are possible.

- The results obtained with this machine are easily fed back to the production machine. We support customers' efficient development and mass production deployment to realize a highly productive mass production environment.

Specifications

The independent unit configuration enables a combination of all of the necessary processing unit(s) in the desired order.

| Coating method |

Slit coater (Die coater)

|

| Coating material |

Materials for solid-state batteries and various rechargeable batteries, PI(polyimide), etc.

|

| Substrate type |

Metal foil, resin film, etc.

|

| Substrate width |

Max. 700mm

|

| Transfer speed |

Max. 80m/min

|

| Coating film thickness |

Max. 250μm

|

| Suitable viscosity |

1 to 10,000 mPa・s

|

| Drying method |

Hot air furnace (a push-pull method selectable)

|

| Hot air discharge temp |

Max. 130℃(standard spec.) |